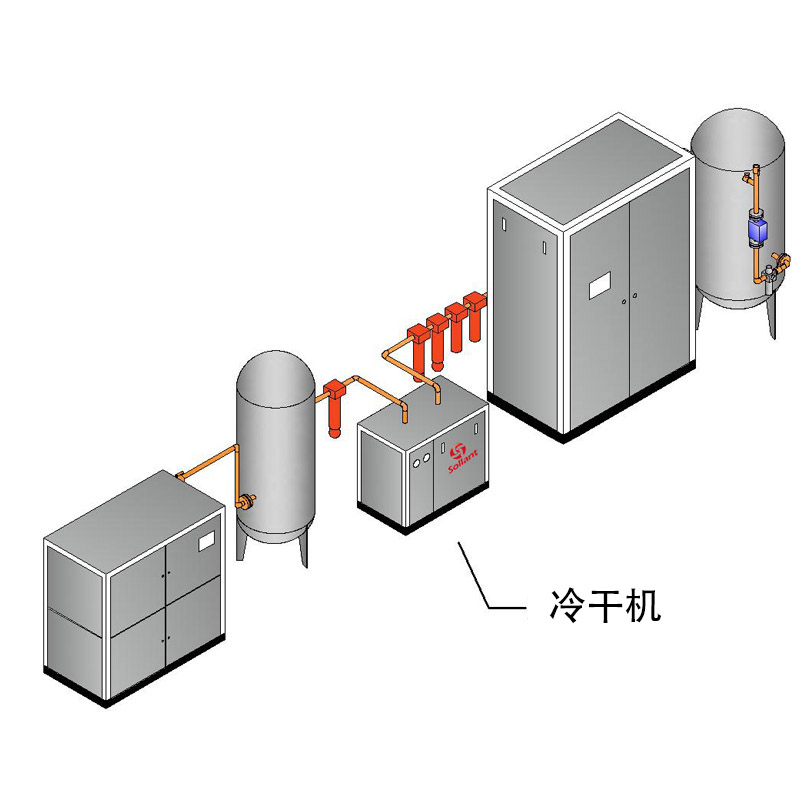

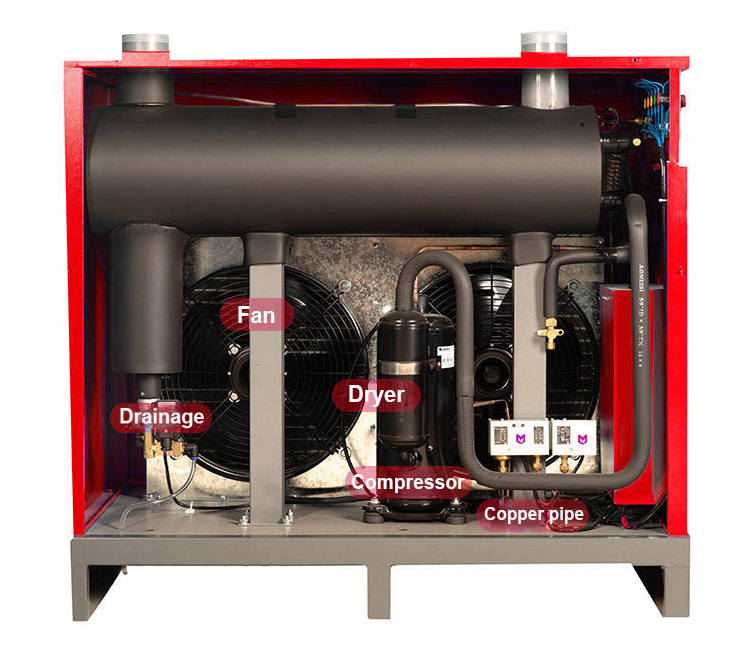

Refrigeration dryer

Direct Driven 15kW 20 hp Rotary Screw Air Compressor with air dryer and tank integrated Machines for Laser Cutting,Local Service Location:

Philippines, Mexico, Russia,After-sales Service Provided:

Online support,Core Components:PLC, Gear, Pump, Bearing,$4,049.00 – $4,100.00/ Set|1 Set/Sets(Min. Order)

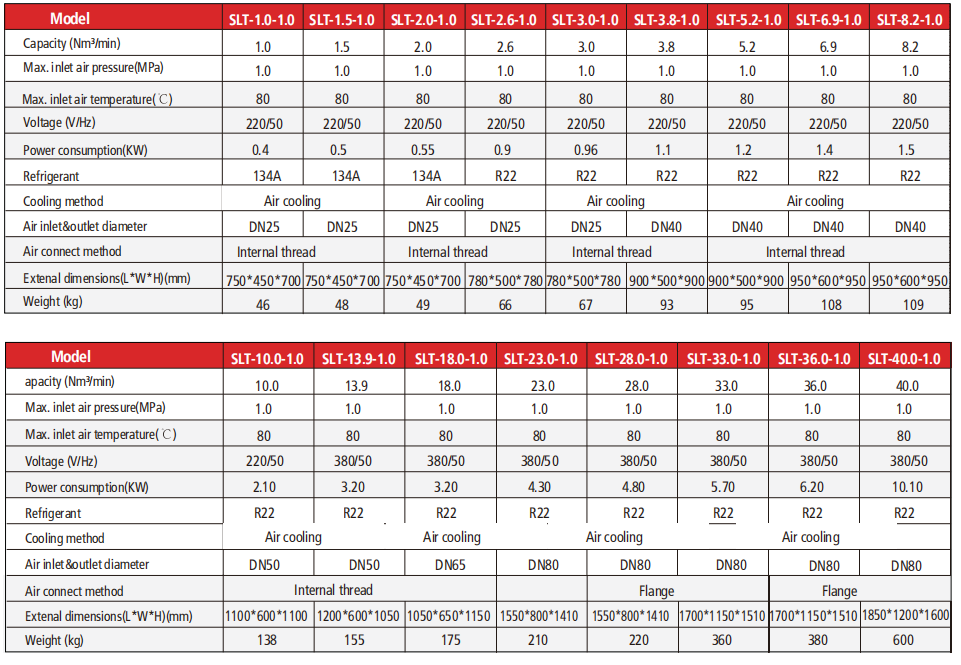

Zollant has customized a matching air compressor for the cutting industry, which can meet the demanding requirements of various laser cutting equipment for water, oil, and particles in compressed air. The product adopts five-stage filtration and non-heat regeneration adsorption dryer. Pressure dew points up to -20 ° C ~ 70 ° C.

To explore in the cutting machine industry, the cost of liquid oxygen per barrel is generally about 70-90$. If your machine work 8 hours a day, you can consume this barrel of oxygen in about 4 days. The average cost of oxygen reduction is 19$ per day. If you are interested in reducing the cost of using the air compressor for laser cutting industry, feel free for contacting Zollant.